Scientists are discovering and identifying promising refractory materials that undergo large temperature changes when subjected to pressure and other forces.

The materials used in air conditioner

Several years ago, researchers at the Polytechnic University of Catalonia and the University of Cambridge conducted a series of simple experiments that could lead to massive results and impacts in the field of air conditioning and refrigeration.

In these trials, they added oil to a chamber containing plastic neopentyl glycol crystals, a substance commonly used in the manufacture of paints and lubricants, and then used a piston to increase the pressure in the chamber. As the applied pressure increased and the liquid was compressed, the temperature of the crystals rose by about 40 °C.

Results and discussion

When the results were published in a paper in Nature Communications last year, they represented the largest temperature shift ever recorded from subjecting materials to stress. While decompression had the opposite effect; As it led to a significant decrease in the temperature of the crystals and their cooling.

The research team said the findings highlight a promising approach to replacing traditional refrigerants, which could provide "environmentally friendly cooling while maintaining the same level of performance". Such developments are of great importance. Because increasing wealth, a growing population, and rising temperatures could triple the energy demand for internal cooling by 2050 if significant technical improvements are not achieved, according to the International Energy Agency.

Thermal change

The temperature change of these materials was close to that of HFC refrigerants in standard refrigerators and air conditioning systems. However, HFCs are one of the greenhouse gases that have the most environmental impact.

This work is based on a long-known phenomenon, familiar to you if you've ever stretched out a balloon and touched it to your lips, whereby pyrotechnics give off heat when placed under pressure or stress. Subjecting certain materials to magnetic and electric fields, or a combination of these forces, leads to the same result in some cases.

Based on these ideas, scientists have been creating magnetic coolers for years, but they demand very huge, very strong, and very expensive magnets.

However, researchers are making significant progress in this area, according to a review paper published in Science on November 12 by Xavier Moya and ND. Mathur, the two materials scientists at the University of Cambridge worked on the aforementioned experiments.

Heating and cooling devices

The authors note that the research teams succeed in accurately identifying many refractory materials that undergo large temperature changes, and then use them in prototypes for heating and cooling devices. Materials and devices that can release and transfer large amounts of heat by relying on electricity, stress, and pressure—technologies that only took off a little more than a decade ago-achieve a performance comparable to that achieved by decades of work in magnet-based refrigeration devices.

In addition to reducing the need for HFCs, it is hoped that this technology may eventually be more energy efficient than standard refrigeration devices, given the heat released as a measure of the amount of energy needed to cause the temperature change. The fundamental difference in this technology is that the materials remain in a solid state, whereas conventional refrigerants, such as HFCs, work by converting between the gas and liquid states.

Triggering a change in the state of matter

Here's how this technology works:

Many materials show small temperature changes when subjected to certain forces. But scientists have been relentlessly seeking to discover materials that undergo large changes in temperature and, in an optimal state, as a result of the lowest possible amount of energy. Among many materials, some metal alloys have shown promising results under stress, while some types of ceramics and polymers respond well to electric fields, and inorganic salts and rubber appear to be promising materials when subjected to stress.

The power of this technology

These forces, or fields, cause atoms or molecules within materials to line up in more orderly ways, resulting in a change of state similar to what happens when flowing water molecules become compacted ice crystals. (In the case of refractory materials, the change of state occurs while the materials remain solid, but in a state in which the materials are more solid than before.) This process releases enough latent heat to equalize the energy difference between the two states. When materials return to their original state after no longer being subjected to other forces, they produce a drop in temperature that can then be exploited for cooling.

This approach is similar to how refrigeration equipment works today; They depressurize the hydrofluorocarbons to the point where they change from a liquid to a gaseous state. But the solid-state cooling method may be more energy efficient, at least in part. Because you don't have to move the molecules as much to cause a change of state, says John Cowie, chief scientist in the Ames lab.

Moving to the stage of production and marketing

The key to delivering competitive commercial appliances is to identify affordable materials that are subject to large temperature changes, can easily return to a previous state, withstand extended cycles of such changes without failure (commercial refrigerators can run for millions of cycles), and are cheap.

Some materials and use cases are close to making it to the commercial market, says Ichiro Tekuchi, a materials scientist at the University of Maryland. Tekuchi launched a stress-responsive coolant company about a decade ago, called Maryland Energy & Sensor Technology.

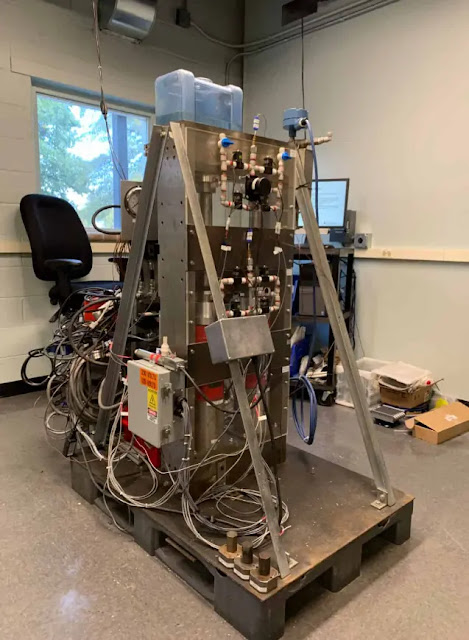

His research group has developed a prototype refrigeration device that increases and decreases pressure on nickel-titanium tubes to induce heating and cooling. The water passing through the tubes absorbs heat during the initial stage, and then the process is reversed to cool the water that can be used to cool a pot or living room.

A prototype refrigeration device developed by Ichiro Teikoshi's research group.

The company plans to produce a wine cooler that does not require the same cooling power as a large refrigerator or a window-mounted AC unit, as an initial product using an unspecified but less expensive material.

Moya, one of the paper's authors, also co-founded his own company about a year and a half ago. The company, Barocal, based in Cambridge, England, has presented a heat pump prototype based on plastic crystals that are "related to neopentyl glycol, but better," Moya says.

Finally, a dozen or so startups have been established to commercialize the technology, and several established companies have explored its potential, including Chinese home appliance giant Haier and the Astronautics Corporation of America.

Cui predicts that we will see some of the first commercial products based on materials that change the temperature in response to force and stress within the next five to 10 years, but he says it will take years for prices to become competitive with standard refrigeration products.

Comments

Post a Comment